Overall size: length * width * height = 1445*1250*2000

Weight: 1000 KG

Power supply: AC220V ± 20V

Power: 50-60HZ

Equipment capacity: 4 KW

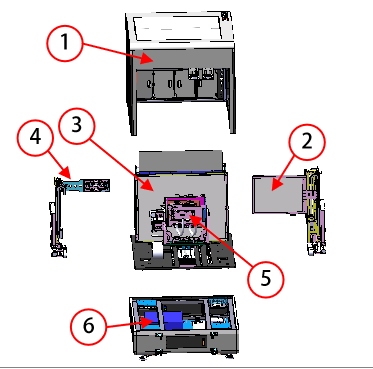

NO. | NAME | Quantity |

1 | Upper frame module | 1 |

2 | AFC-stain test | 1 |

3 | AFC-chart | 2 |

4 | AFC-Distant and close | 1 |

5 | AFC-Rotating module general map | 1 |

6 | Chassis mounted | 1 |

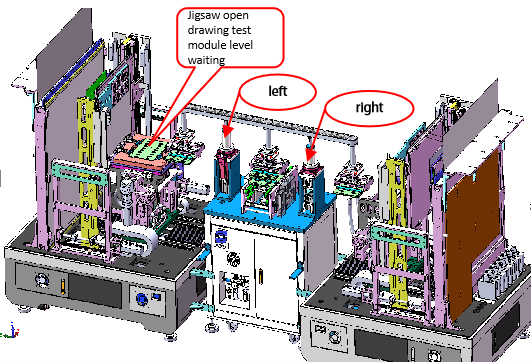

The first step is to manually load the material to the expanded silo, and the expanded silo sends the material to the rotary loading and unloading machine. The direction of the arrow is the flow direction of the imposition. (One robot on the left and right for rotating, loading and unloading corresponds to one on the left and the right for loading)

In the second step, the mechanical arm of the rotating loading and unloading machine first rotates 90 degrees and then descends to suck the puzzle through the vacuum suction cup. After getting the jigsaw, go up again, and then rotate 180 degrees to lower the jigsaw.

In the third step, after the jigsaw test module is connected to the jigsaw, the cylinder moves to block the jigsaw. Then the rotating module rotates 90 degrees counterclockwise, and then the transplanting axis moves to send the puzzle to a specific position for drawing.

In the fourth step, after the opening test of the jigsaw puzzle is completed, the transplanting shaft is first retracted, and then the turning shaft is turned 90 degrees clockwise to return to position, and the four cylinders move outward to release the jigsaw, waiting for the rotating reclaiming manipulator to take the material away.