This equipment performs.

Optimize optical and image quality for 2 devices using active alignment (AA).

Fixation or pre-cure bonding process of 2 devices onto metal bracket.

UPH : 270

Up to 6 Degree of freedom alignment

Parallelism at ±0.08°

Intersecting angle at < 0.05°

Capable of dot and line dispensing, consistency at 99.8%.

Programmable dispensing parameters; such as feed rate, stop time, thickness control (z-axis); for all type of adhesive shape requirement.

Automatic placement positioning compensation via machine vision systems, integrated triple pick & place module.

The equipment is designed for both standalone and scalable in-line production operations.

It is clean-room class 100 or ISO 5 ready.

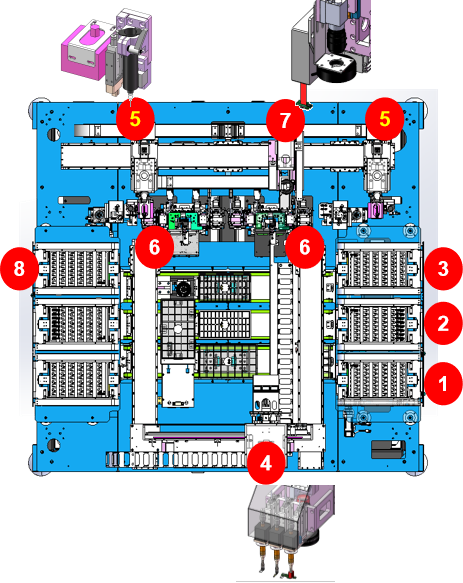

Device A input feeder.

Device B Input feeder.

Metal Bracket Input feeder.

Triple pick & place with CCD positioning module.

Dual Dispensing and UV cure pick & place modules.

Dual Active Alignment (AA) stations.

CCD Vision systems and laser height measurement.

FG Output module.