This equipment performs.

Optimize optical and image quality of a single device using active alignment (AA).

Fixation or pre-cure bonding of Lens VCM module onto the Sensor.

UPH : 400

Up to 6 Degree of freedom alignment

Single or multiple point marking for same or different defined action/s on the same product.

Capable of dot and line dispensing.

Programmable dispensing parameters; such as feed rate, stop time, thickness control (z-axis); for all type of adhesive shape requirement.

Automatic placement positioning compensation via machine vision systems.

The equipment is designed for both standalone and scalable in-line production operations.

It is clean-room class 100 or ISO 5 ready.

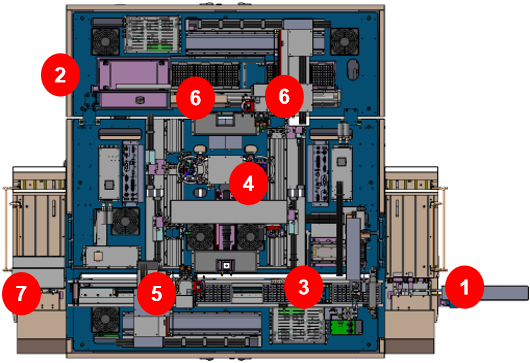

Input A feeder - Sensor.

Input B feeder – Lens module.

CCD Vision systems.

Pick & Place for A – Sensor.

Adhesive dispensing and UV curing station.

Dual Active Alignment stations

FG Output module.